The World's First Direct Seawater Electrolysis for Hydrogen Production Driven by Offshore Wind Power Successfully Tested in Fujian. This groundbreaking technology, developed through a collaboration between the academician team of Xie Heping from Shenzhen University/Sichuan University and Dongfang Electric Corporation, underwent rigorous offshore pilot demonstrations in Fujian. The offshore pilot demonstration of the coupling technology of offshore wind power and direct electrolytic hydrogen production from seawater without desalination put to the test, demonstrating over 240 hours of continuous stable operation. It successfully verified for the first time the reliability of the technology of seawater desalination-free in-situ direct electrolytic hydrogen production by Chinese scientists under the real marine environment with 3-8 grade wind and 0.3 - 0.9 meter wave interference, and built an integrated seawater direct hydrogen production plant combined with renewable energy, which is expected to create a global offshore renewable energy direct hydrogen production plant, and promise to create a global benchmark in the field of offshore renewable energy direct seawater hydrogen production.

Academician Xie Heping's team has solved almost half a century’s global challenge in this field. Their groundbreaking research on hydrogen production from seawater, initially published in the renowned scientific journal Nature on November 30, 2022, has received recognition as one of the top ten advancements in Chinese science for the year 2022. Building upon this pioneering principle and technology, Dongfang Electric Corporation and Xie Heping's team have specially developed a floating offshore hydrogen production platform (9m×7m×3.5m) and a smart and stable power supply system for offshore wind power. From May 17 to 26, 2023, the platform was deployed and connected to an offshore wind power system located in the Xinghua Bay of Fuqing City. During its ten-day trial, the system demonstrated continuous and stable operation, marking a milestone as the first successful sea trial of direct electrolysis for hydrogen production from offshore wind power without the need for desalinated seawater.

The test data from the third-party technical testing institution (Sichuan Quality Inspection Institute) reveals that the scale of hydrogen production in this sea trial reaches 1.3 Nm3 H2/h, which exceeds the design value. The energy consumption of electrolysis is recorded at 5 kWh/Nm3 H2. Also, even after enduring 10 days of continuous stable operation within the challenging real marine environment characterized by sea winds of 3-8 grade and wave heights of 0.3-0.9 m, the ion barrier rate of seawater impurities remains impressively high at 99.99% (Comparable to direct electrolysis of pure water for hydrogen production). The purity of hydrogen production demonstrates excellent stability, reaching levels between 99.9% and 99.99%.

The new technology of this sea trial eliminates the need for costly engineering processes such as seawater desalination, seawater transportation, and the treatment of seawater pollution after desalination. As such, the cost associated with this innovative approach is only approximately 15.89-21.49 Yuan/kg H2, slightly higher than the cost of grey hydrogen from coal (9-12 Yuan/kg H2) and significantly lower than that of blue hydrogen derived from natural gas (20-24 Yuan/kg H2). As offshore wind power technology continues to progress and feed-in tariffs decrease in the future, the cost of direct hydrogen production from seawater is anticipated to become even more economical than the cost of coal-based grey hydrogen production. This sea trial involved three sets of principle prototypes (0.4 Nm3/set) in parallel to establish an equipment system designed to achieve a hydrogen production scale of 1.2 Nm3/h. The success of this trial serves as a direct verification for the future realization of large-scale seawater direct hydrogen production in parallel, ranging from 10 to 100 Nm3/h.

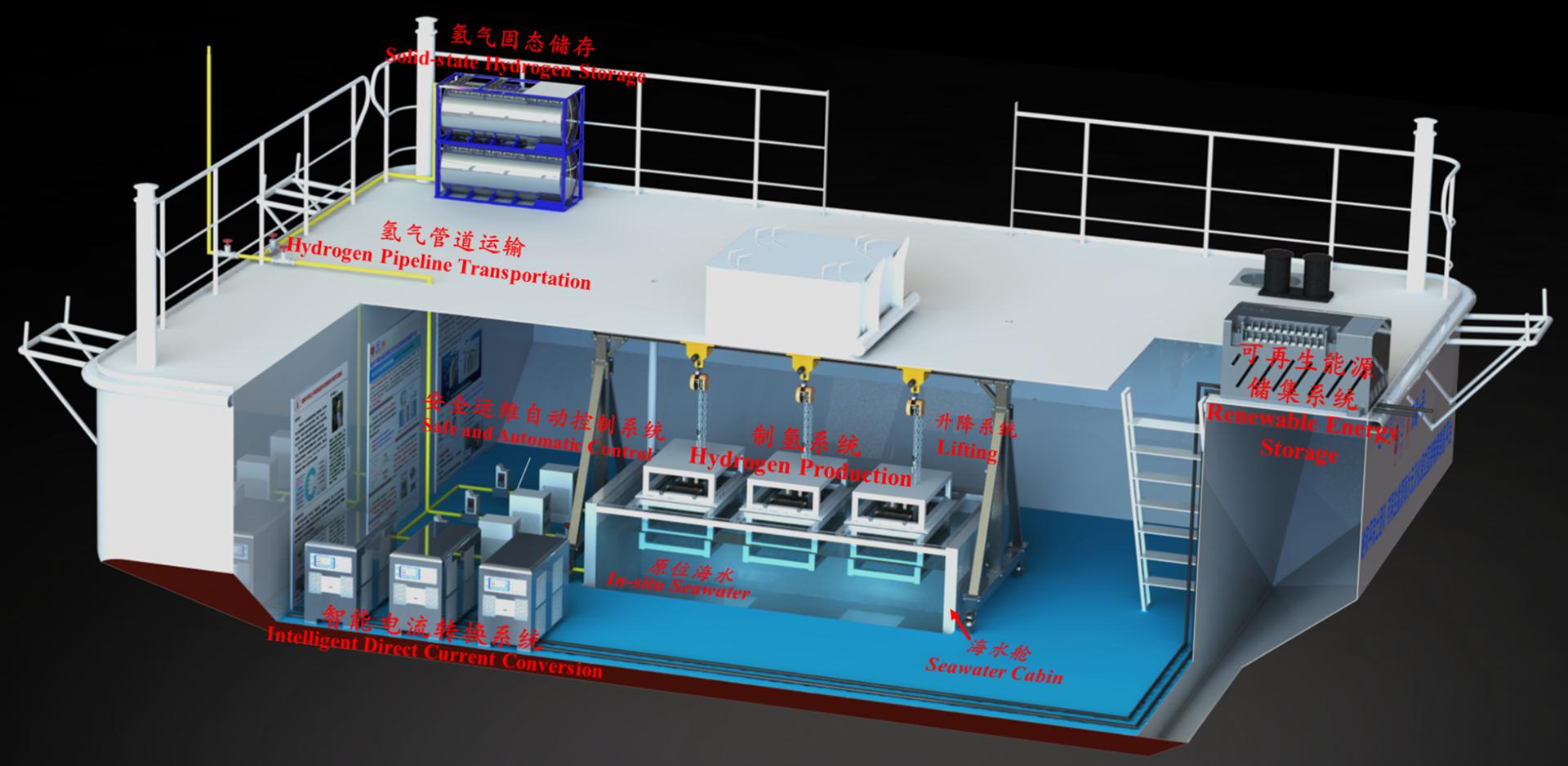

图1:"Floating platform "Offshore wind power and other renewable energy utilization and seawater hydrogen production

图2:Renewable energy seawater desalination-free in-situ direct electrolysis hydrogen production platform

图3:Academician Xie Heping's team builds the world's first demonstration project of in-situ direct electrolysis of hydrogen from seawater without desalination for offshore wind power

On December 16, 2022, a mere 16 days after the publication of the Nature paper, Dongfang Electric Corporation made a dedicated investment of 30 million RMB specifically for research and development funding and cooperated with the alliance of Xie Heping's team to jointly propel the industrialization and practical implementation of in-situ direct electrolysis for hydrogen production from seawater, without the need for desalination.

This offshore experiment of 1.2 Nm3 H2/h seawater desalination-free in-situ direct electrolytic hydrogen production with energy storage system with 28kW output power conducted by Dongfang Electric Corporation and Xie Heping's team in Fuqing County, Fujian Province, has achieved stable hydrogen production for a duration of 10 days, demonstrating a Faraday efficiency approaching 100%. The energy consumption and experimental outcomes obtained from this offshore experiment exhibit comparability to those observed in laboratory settings. At the same time, the joint research team also capitalized on the opportunity provided by this sea trial to conduct a comprehensive performance evaluation of direct hydrogen production from seawater in a real marine complex environment, analyzed and compared the key differences with the laboratory hydrogen production effect. The investigation explored the implications on the steady-state equilibrium of electrolytic hydrogen production, the phase-transition migration process driven by offshore renewable energy power, as well as the comprehensive performance of core materials and components within the electrolysis equipment, The acquisition of valuable demonstration verification data brings about a new path for the cutting-edge results published in the top issue of Nature to " practical implementation and industrialization of these breakthroughs" as soon as possible.

图4:In-situ direct electrolysis of seawater without desalination for hydrogen production live test

"This is the first and pivotal stride in our three-step strategy towards ushering in a new era of global direct electrolysis of hydrogen from seawater," stated Academician Xie Heping. “We have successfully bridged the offshore renewable energy and realized the direct electrolysis of seawater to produce hydrogen without need for desalination in the real and complex environment of the ocean. Moving forward,, in the second step, we will make every effort to delve into the second generation of core technology of direct electrolysis of hydrogen from seawater that can withstand the challenges posed by marine environmental interferences, We will diligently develop second-generation technology and equipment with higher efficiency, higher compatibility and higher stability, so as to consistently maintain a leading position in the principles and technologies of desalination-free hydrogen production from seawater, thereby spearheading the new paradigm of global non-pure water electrolysis for hydrogen production. The third step is to forge an industrialization alliance with Dongfang Electric Corporation for global enterprises to fully promote industrialization. Concurrently, our team will explore third and fourth-generation core technology and equipment that are more scalable and intelligent, pioneering the integration of renewable energy sources like offshore wind power with direct electrolytic hydrogen production from seawater in an innovative industrial framework, therefore to bring about benefits for mankind!"

The success of the sea trial fully signifies a big step forward in the industrialization process of direct electrolysis of hydrogen from seawater without desalination, marking the official transition into a new era of direct electrolysis of hydrogen from seawater! The widespread adoption and implementation of this technology will really create a new marine green hydrogen industrial system integrating "offshore wind power and other renewable energy utilization - seawater resource utilization - hydrogen energy production". This system is expected to establish a novel model of in-situ direct electrolytic hydrogen production, eliminating the need for desalination, additional catalyst engineering, seawater transportation, and pollution treatment. It will truly bring the inexhaustible "seawater resources" into the "seawater energy"! At the same time, it can build an integrated in-situ seawater hydrogen production plant combined with offshore renewable energy in the future. This development will play a pivotal role in the large-scale development of renewable power in the near deep sea, and expedite the formation of China's original "ocean green hydrogen" global emerging strategic industry with multiple energy complementarity! It will also facilitate the formation of a comprehensive zero-carbon hydrogen energy development pathway in China, encompassing fundamental principles, disruptive technologies, localized equipment, and distinctive electrolysis hydrogen production industrial models. By providing China's innovative solutions, wisdom, and standards for zero-carbon energy along the carbon-neutral trajectory, this advancement will contribute to China's efforts in achieving carbon neutrality and promoting the development of zero-carbon hydrogen energy!