The "two lines and three hubs"of Shenzhen Metro will open for operation by the end of October 2022, marking a new step in Shenzhen's urban rail transit construction. Among them, the operation of Gangxia North Hub, Huangmugang Hub and Dayun Hub will effectively relieve the pressure of urban traffic, meeting people's travelling needs and promoting the sustainable and healthy development of the regional economy. Since April 2020, the research team, led by Academician Chen Xiangsheng, Dean of the School of Civil and Traffic Engineering at Shenzhen University, has carried out technical research to break through a series of "neck" problems faced in the construction of mega-hubs in the complex environment of busy urban areas, providing strong technical support and safety guarantee for the smooth opening and operation of the three hubs.

Fig.1 In April 2020, Academician Chen Xiangsheng led a research team to

Universiade

Fig. 2 The Future Underground City Research Institute team provides the whole process technical support for the construction of the hub

1.Underground space large diameter fish-bellied V-shaped columnPermanent-temporary structurestructural system conversion

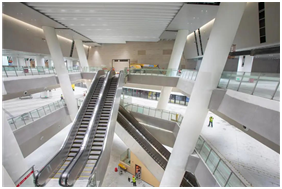

Huangmugang comprehensive transportation hub project is a three-line interchange hub of Shenzhen existing metro line 7, line 14 and line 24, an important node on the central development axis of Shenzhen rail transport.For the first time, the fish-bellied v-shaped column structure was adopted in the underground space of the core area of line 24 of metro junction,with a total of 50 steel columns in 25 combinations, with a maximum single length of about 38.5m, a weight of about 87t and an inclination angle of 1.3°-13°.

Fig. 3 Fish-belly V-shaped column structure system in underground space

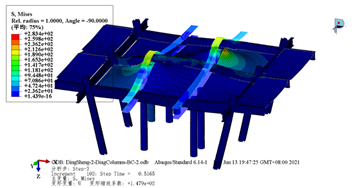

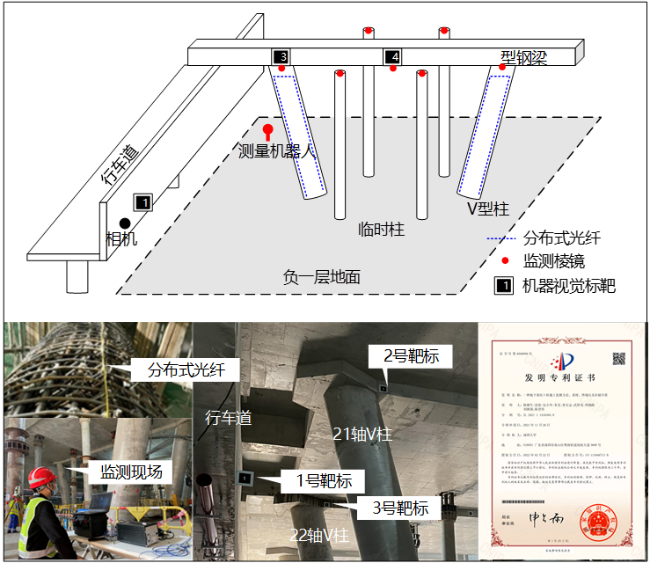

The pivot pit was constructed using the cover excavation reverse method. Before the V-columns formed a force-bearing system, the slabs of each floor relied on temporary steel pipe columns to provide vertical support. After the construction of the V-columns was completed, the temporary column jacking servo system was used to complete the conversion of the bearing system, and the structural force system changed several times, which posed a greater safety risk. The team determined the temporary column jacking threshold through 3D refined finite element analysis, and adopted the multi-source sensing technology of "distributed optical fibre + MEMS sensing + machine vision + automated total station" to establish a "coarse-sparse-refined-dense" underground space structure systematically. The intelligent sensing system, through algorithms for real-time diagnosis of system transformation risk, combined with high-precision hydraulic servo system, to achieve millimetre-level control of structural deformation in the process of system transformation.

Fig. 4 On-site monitoring and risk assessment of“Permanent-temporary” structural system

transformation

2. Space truss steel structure system hoisting construction

Dayun Hub is the only large integrated transportation hub in the east of Shenzhen that brings metro, intercity railway and public transport together, and will realize the four-line interchange of lines 3, 14, 16 and SZU intercity in the future. The Dayun Hub covers an area of about 60,000 square metres, with a planned construction area of about 173,200 square metres. The roof is themed on the "Dance of the Bay Area", with an overall floating and agile design, which is highly aesthetic.

Fig. 5“Bay Area Dance” steel structure ceiling

The spatial truss steel structure system used for the roof of the hub is complex in terms of stresses,with high precision in processing and installation, and challenging to construct. Based on the design and construction plan of the large-span steel roof, the team optimised the structural system and other key parameters affecting the structural performance, and analysed the safety of protective equipment, lifting equipment, transport equipment and their supporting structures during construction to enhance the technical advancement, economy and safety of the project from design to construction.

Fig. 6 Study on hoisting safety of space truss steel structure system

3. Construction deformation control of oversized deep foundation pits adjacent to operating metro stations

The new foundation pits of Dayun and Huangmugang hubs, which are expanded from Dayun Station of Shenzhen Metro Line 3 and Huangmugang Station of Shenzhen Metro Line 7 respectively, have a large area and depth, and are closely spaced to the existing operating stations, making deformation control extremely difficult. Based on the characteristics of the hub stratum and surrounding structures, Chen's team established a 3D refined model, analysed the force deformation characteristics of the existing above-ground and underground station structures and pile foundations during the construction of the immediately adjacent deep foundation pit, and proposed targeted deformation control measures. MEMS sensors, automated total station, visual displacement and other technologies were used to intelligently sense the deformation of the foundation pit and existing stations; a deformation prediction and early warning platform was developed, and five artificial intelligence algorithms were embedded in the platform to predict and warn structural deformation, ensuring the safety of the foundation pit and existing station structures during the whole excavation process.

Fig. 7 Fine simulation of super-large deep foundation pit adjacent to the existing station

Fig. 8 Prediction and early warning system of intelligent sensing and deep learning of hub

deformation