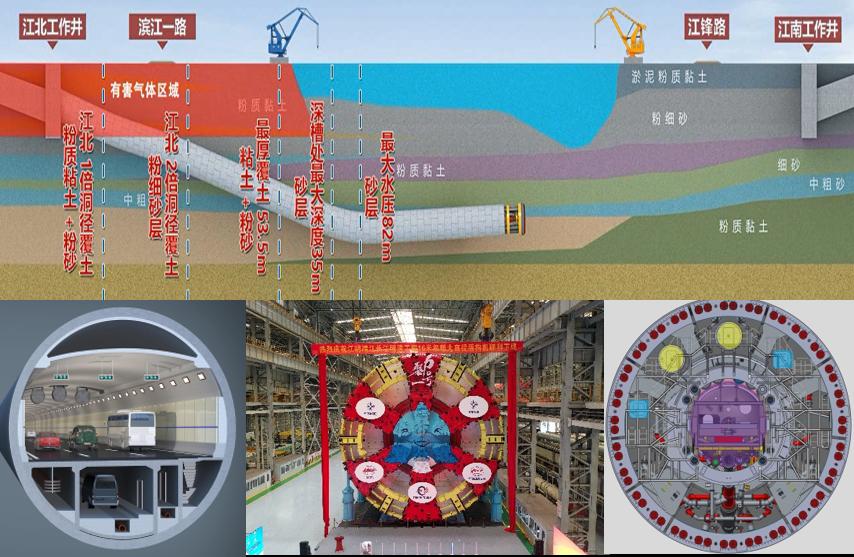

The Jiangyin-Jingjiang Yangtze River Tunnel is 6,414 meters long, with a shield section of 4,952 meters and an outer diameter of 15.5 meters, which was regarded as “the largest diameter shield tunnel in Mainland China” at that time. The tunnel is constructed according to the standard of two-way six-lane highway, with a design speed of 80 km/h, and adopts shield tunnel to cross the Yangtze River bottom. Designed to withstand a maximum water pressure of 1.2 MPa, it is the largest diameter and the highest water pressure in the construction of the oversized diameter tunnel.

The shield machine had to withstand a head of 82 meters when crossing the bottom of the Yangtze River, which was the largest section and highest water pressure underwater shield tunnel in China at that time. In addition, the shield machine also faced the challenge of powdery clay and fine sand layers (which are high water pressure and strong permeable strata), which undoubtedly increased the difficulty and risk of tunnel construction.

When the shield machine started from the Jingjiang section and dug into the position near the center of the river bottom, the shield main shaft suddenly failed and stopped, resulting in a great challenge to the progress of the project. According to the investigation, the trapped stratum is mainly a fine sand layer, which belongs to high water pressure and strong permeability stratum, with huge potential risks. If the two shield buttresses are connected to the bottom of the Yangtze River, the river water will directly flood the shield equipment and cause a huge accident.

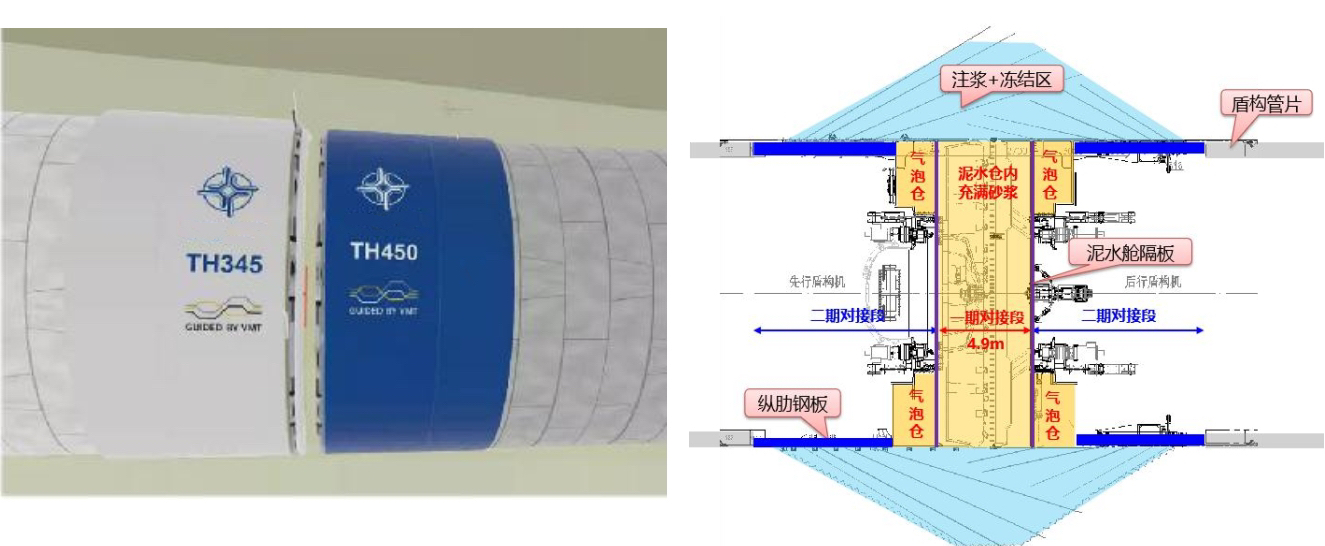

On August 17, 2023, an expert group consisting of nine experts including academicians of the Chinese Academy of Engineering passed the “Jiangyin-Jingjiang Shield Docking Freezing and Reinforcement Program”, and unanimously agreed to adopt the asymmetric freezing program to carry out the freezing and reinforcing construction of the docking section. Academician Chen Xiangsheng of our academy took the lead in undertaking the “Jiangyin-Jingjiang Yangtze River Tunnel Left Line Shield Failure Disposal Freezing Design and Monitoring Consultation”. And put forward “first grouting, then freezing”, the use of freezing pipe instead of drilling rod, to achieve the drilling, grouting and freezing “one rod multi-purpose” innovative program. It not only avoids the ground disturbance caused by repeated insertion and pulling of grouting pipe, but also greatly reduces the amount of freezing expansion in the process of ground freezing, which lays a solid theoretical foundation and technical support for the successful implementation of this project.

On July 21, 2025, the two shields of the Jiangyin-Jingjiang Yangtze River Tunnel successfully penetrated the ground under the Yangtze River. The maximum freeze-up monitored was 13.3 mm for the advance shield and 14.81 mm for the backward shield, which is much less than the early prediction of 100 mm. The thawing and sinking stage has reached 34 days, and the maximum thawing and sinking amount is only 4.52 mm at present, which is much lower than the early warning value. The above results show that the technical measures proposed by our institute are targeted and very effective. It is the first time in the world that the technology of buttressing and freezing reinforcement in shield ground in high water pressure and strong permeability stratum is successful, which is of great significance to the underground engineering industry as a milestone. This also fully embodies the spirit of our institute to face up to the challenge of the major engineering risk of the two shield buttresses in the river bottom stratum, and the spirit of bearing the major engineering risk with all the colleagues of the participating units and the dedication of scientific and technological workers to the country; it is also the true portrayal of the scientific and technological workers in our institute, represented by Academician Chen Xiangsheng, to write their thesis on the motherland.